What?

Composites are materials made out of two or more distinguishable materials that each contribute with specific functions. In that way, it is possible to customise materials by combining materials with different properties.

A commercial group of composites for product design is called Wood-Fibre Composites. These are predominantly made of renewable and degradable resources.

Why?

Composites make it possible to customise materials for specific applications, e.g. by high strength, low weight and durability. Furthermore, by working with the composition of materials, non-homogeneous and topology optimised materials can be obtained.

Challenges

- To utilise a composite’s elements best, it should be developed for a specific product. This can make development time-consuming and costly.

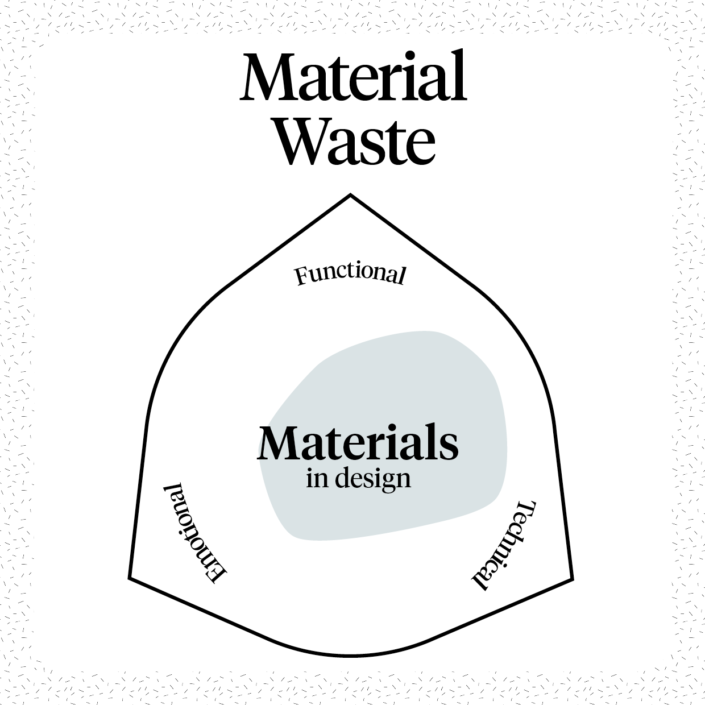

- Composites are difficult to disassemble and thereby material recycling can be complicated.

Examples

- Animal bones are made of hard and brittle hydroxyapatite and soft and flexible collagen.

- Most of the Airbus A350 XWB’s wing and frame is comprised of lightweight carbon composites that due to the lighter weight, require less fuel to move.

- The core of the iconic Panton chair manufactured by Vitra is made of glass-fibre reinforced polyester.

Further Reading

Bunsell & Renard. (2005). Fundamentals of Fibre Reinforced Composite Materials. Series in Materials Science and Engineering. Taylor & Francis.

Callister (2006). Composites (Chapter 16). In: Materials Science and Engineering, Wiley and Sons, pp. 577–620.