What?

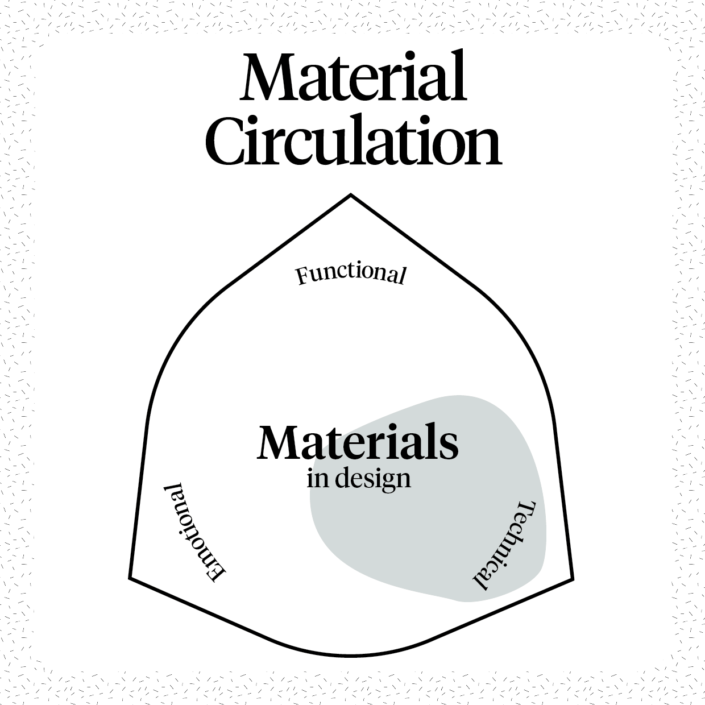

Material plurality considers the use of different materials in products due to the need for material functionalities. Sometimes this is also called ‘material diversity’. An approach to this is working with mono-materials, where a single type of material is used for each component of a product so that it can be split apart after use.

Why?

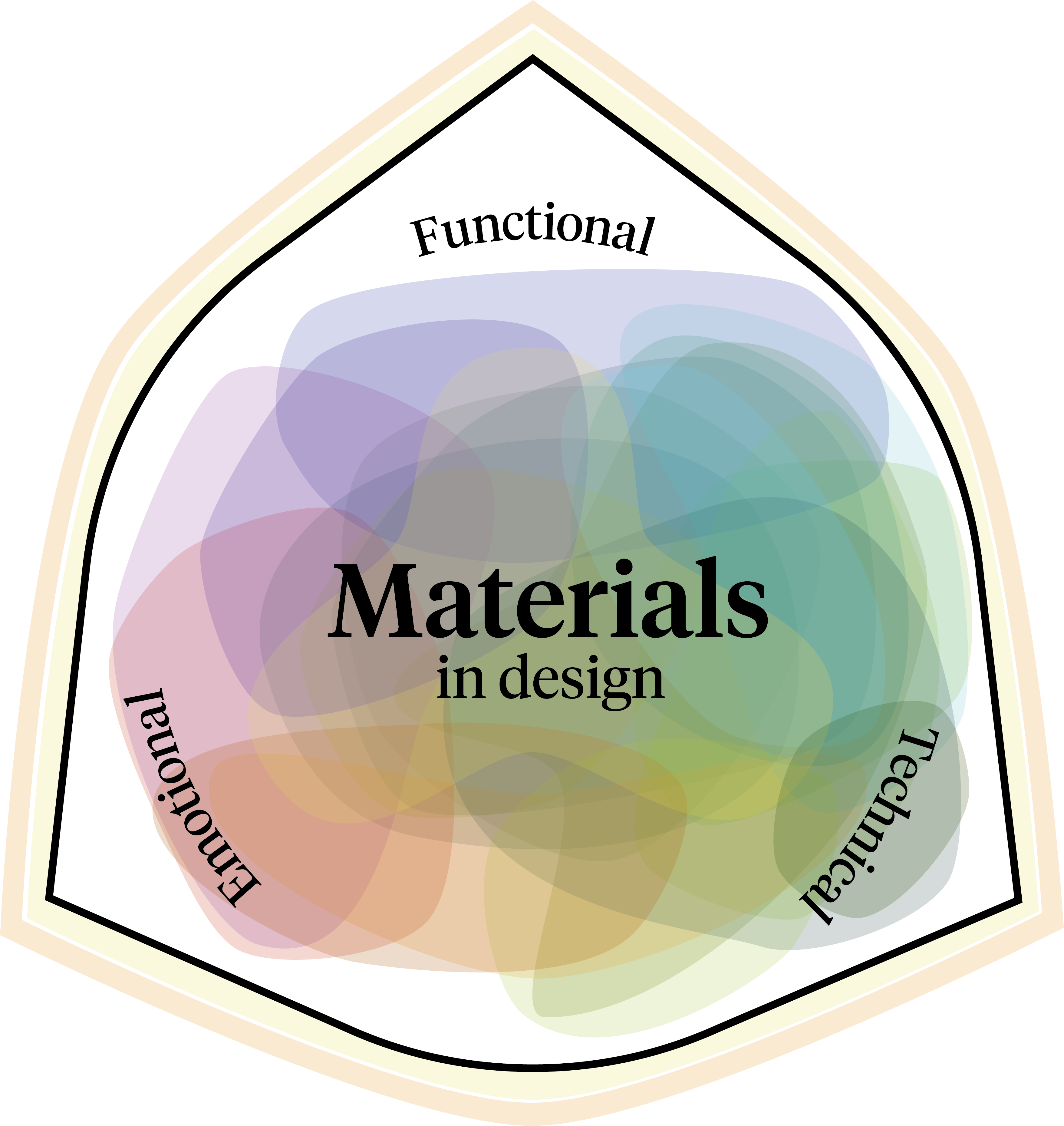

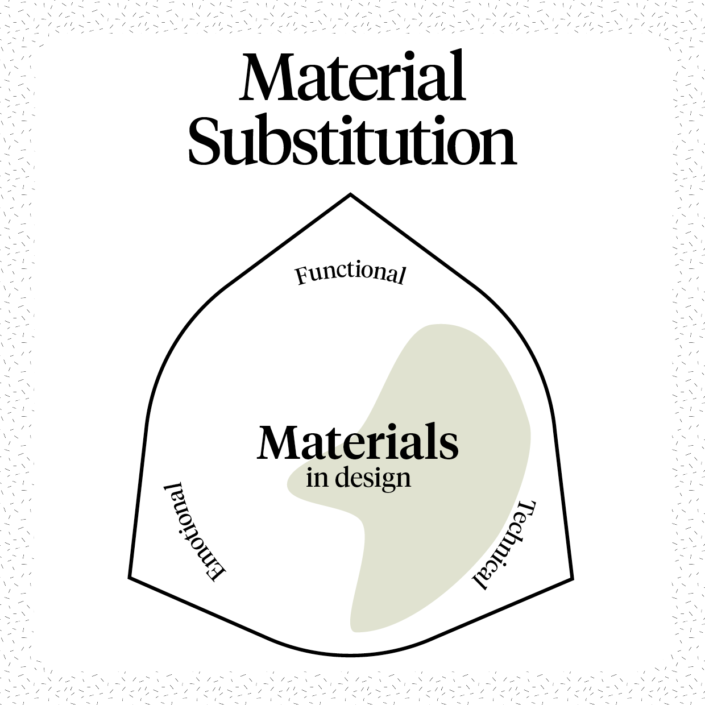

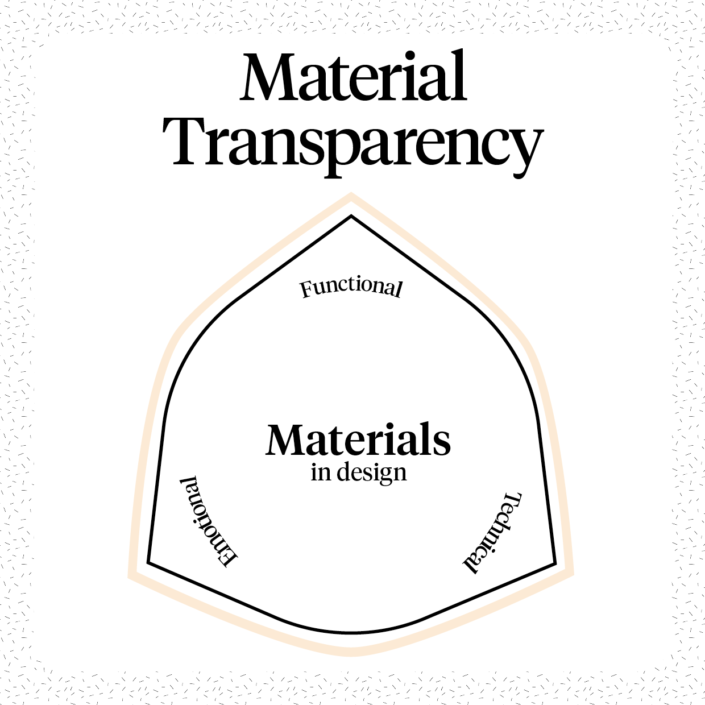

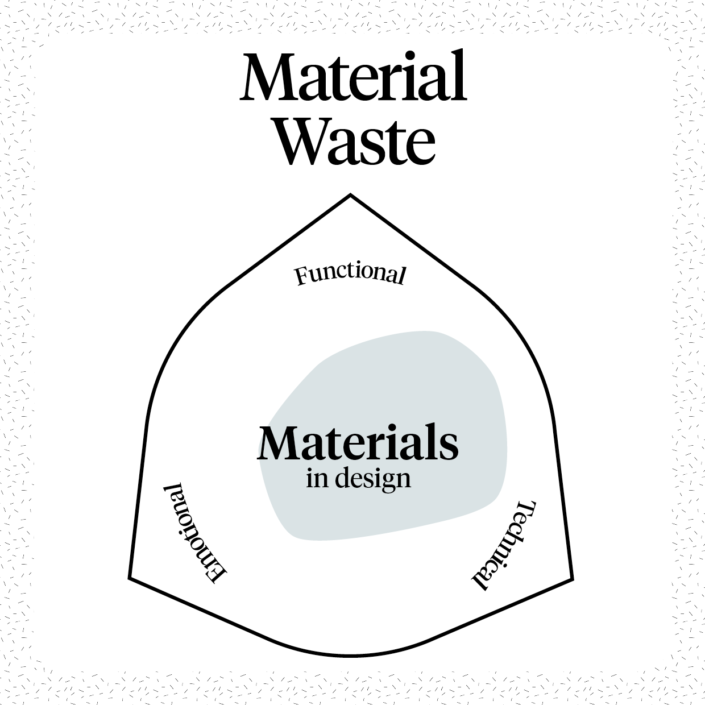

Many products have multiple technical, functional and emotional aspects, which can be supported by using many different materials in one product. This however creates highly complex products.

Challenges

- Material plurality in products challenges repair, re-use and disassembly.

- If products are designed to be disassembled, it is necessary to clearly inform on the materials used.

- It may be necessary to compromise on functionality and aesthetics to lower the number of materials in a product.

Examples

- Lilian van Daal’s chair concept utilises biomimicry and 3D printing to provide a mono-material alternative for conventional soft seating.

- In jumbo aircrafts, there are between 3,000,000 and 7,000,000 components.

- Product teardown is an approach to understand a product’s parts, the materials they’re made of and to reverse engineer an alternative product.

Further Reading

McDonough & Braungart (2002). Cradle to Cradle: Remaking the Way We Make Things. North Point Press.

Parajuly & Wenzel (2017). Product Family Approach in E-Waste Management: A Conceptual Framework for Circular Economy. Sustainability 9 (5), pp. 768-781.